Understanding the Different Types of Industrial Scales for Your Business

Understanding the Different Types of Industrial Scales for Your Business

Blog Article

Why to Pick Industrial Scales for Accurate Weight Dimension in Different Industries

In a period where precision is critical, the choice of industrial ranges for precise weight measurement plays a vital function throughout diverse markets. These scales not just boost functional effectiveness but also guarantee conformity with regulative criteria, impacting every little thing from manufacturing to shipping.

Significance of Accurate Weight Measurement

In the realm of industrial procedures, the value of precise weight measurement can not be overemphasized. Precise weight dimension is fundamental throughout different industries, influencing both functional efficiency and product quality - Industrial Scales. It acts as a vital factor in stock monitoring, making sure that materials are appropriately represented, consequently minimizing waste and decreasing costs

In production, precise weight measurement straight affects manufacturing procedures. Abnormalities in weight can result in low quality products or extreme source appropriation, affecting overall profitability. Furthermore, in industries such as pharmaceuticals and food manufacturing, adherence to strict weight specifications is vital for regulative conformity and customer security.

Moreover, precise weight measurements help with reliable logistics and supply chain administration. Appropriately evaluated deliveries make sure that transportation prices are maximized and that inventory degrees are kept precisely, therefore protecting against supply scarcities or overstock situations.

Types of Industrial Scales

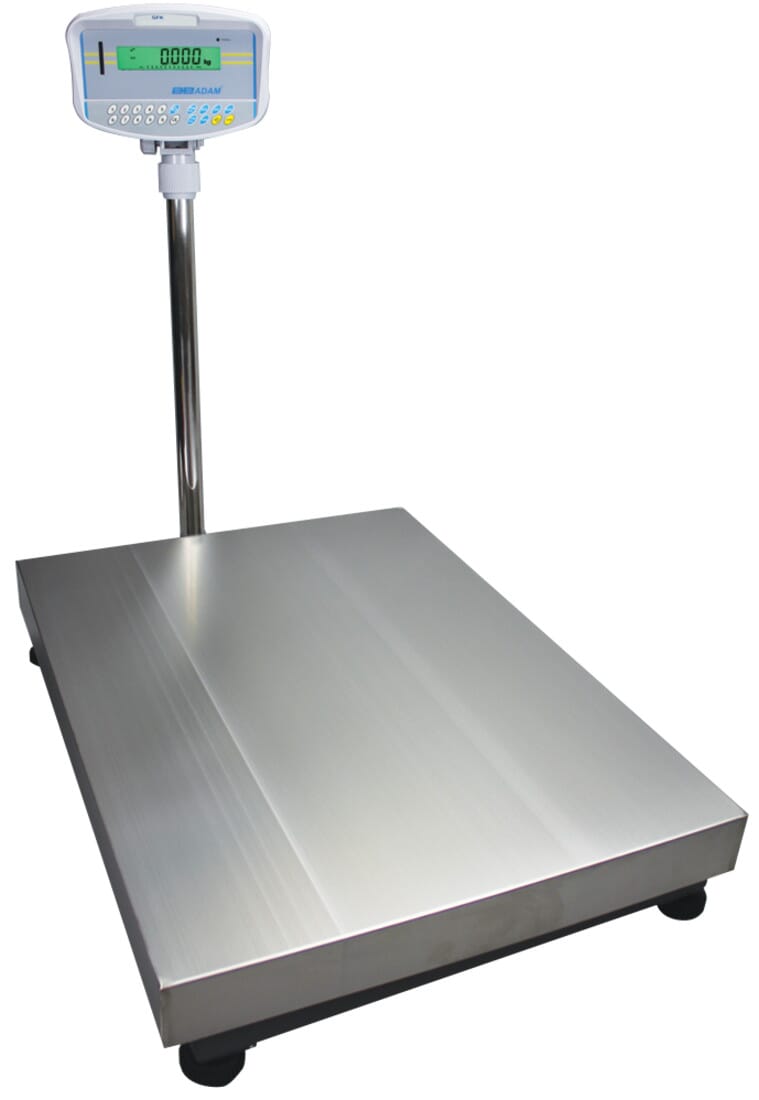

A wide array of commercial scales are readily available, each made to meet certain dimension requires throughout varied fields. Common kinds include floor ranges, which are suitable and robust for evaluating big items or pallets in storage facilities and distribution facilities. Bench ranges are smaller and excellent for lighter products, frequently made use of in retail settings or manufacturing for precise part control.

Another classification is mobile ranges, which provide the adaptability to be moved easily around task sites, making them optimal for field operations or momentary arrangements. Precision ranges, on the various other hand, are developed for high precision and are regularly made use of in research laboratories and quality assurance environments.

Load cells are critical components in different industrial scales, converting force right into an electric signal for exact readings. In addition, vehicle ranges provide the ways to consider heavy cars and their lots, making certain compliance with policies and maximizing logistics.

Finally, checkweighers instantly contrast the weight of items against predetermined restrictions, enhancing top quality assurance in assembly line (Industrial Scales). Each kind of industrial range offers a distinct function, dealing with the specific needs of markets such as manufacturing, logistics, food handling, and pharmaceuticals

Benefits of Making Use Of Industrial Scales

Continually using commercial scales offers considerable advantages throughout various industries. One of the primary benefits is improved accuracy in weight measurement, which is critical for maintaining high quality requirements and regulatory conformity. Exact measurements prevent expensive mistakes in shipping, production, and inventory monitoring, ultimately causing boosted operational performance.

In addition, industrial ranges are created for resilience and effectiveness, enabling them to endure rough environments normally discovered in manufacturing and warehousing. This strength makes certain a lengthy life-span, reducing the need for regular replacements and maintenance prices.

Additionally, utilizing industrial scales boosts safety and security and minimizes waste. By making certain that products are weighed accurately, companies can prevent overloading vehicles, which can bring about fines and crashes.

Applications Throughout Numerous Industries

Industrial scales play a crucial function in countless sectors, consisting of production, logistics, food handling, and drugs. In production, these ranges are vital for guaranteeing that resources are measured accurately, thus preserving product top quality and consistency (Industrial Scales). Accuracy in weight measurement directly impacts manufacturing performance and cost monitoring

In logistics, commercial ranges facilitate the accurate considering of deliveries, which is important for adhering to maximizing and delivering policies freight expenses. Accurate weight information aids improve procedures and boosts supply chain management.

The food handling market counts greatly on commercial scales for compliance with health and wellness regulations. They are used to weigh active ingredients specifically, ensuring that solutions fulfill both high quality criteria and legal requirements. This is important not only for consumer security however likewise for preserving brand honesty.

Pharmaceutical his explanation business use commercial scales to make certain precise does in medicine production, where also the tiniest inconsistency can have considerable repercussions. Conformity with rigorous governing criteria makes exact weight dimension crucial in this sector.

When Picking Ranges,## Elements to Consider.

Selecting the right range for certain applications requires cautious factor to consider of numerous variables. The ability of the scale is essential; it must suit the optimum weight of the items being gauged without exceeding its limitations. Furthermore, the readability, or smallest increment the scale can properly show, is essential for precision, particularly in markets where weight discrepancies can cause substantial economic losses or security concerns.

Environmental problems also play a significant role in scale choice. For example, scales made use of in destructive or humid atmospheres might call for specialized products to ensure durability. In a similar way, mobility may be important in specific applications, requiring lightweight and battery-operated versions.

Verdict

In final thought, the selection of industrial scales is pivotal for making certain exact weight measurement across diverse industries. Thus, investing in top quality industrial scales is vital for organizations intending to preserve high standards and make the most of productivity.

Report this page